Blending gas

Discover how blending gases such as hydrogen and biomethane into the natural gas network can help decarbonise our energy system.

What is blending?

Blending is the process of mixing low-carbon gases such as hydrogen or biomethane with natural gas in the existing network.

This reduces carbon intensity while maintaining compatibility with current infrastructure, helping to decarbonise energy supply without major system changes.

Blending value chain

The value chain highlights the key stages in the blending process, from production to end use.

Gas blending involves carefully controlled processes to mix different gases in precise proportions. Typically this occurs at blending facilities, where gases like natural gas, hydrogen or biomethane are fed into a network of pipelines and mixing chambers. Advanced sensors and control systems then make sure the gas blend achieves the exact composition needed.

Real-time monitoring helps track flow rates, pressures and the final mixture's properties, so adjustments can be made if required. This enables consistent gas blends that meet strict quality and safety standards.

Once blended, the gas blend flows seamlessly through existing or new pipelines, with monitoring systems making sure the blend maintains a high level of quality at all times.

The gas blend is now ready for use in homes and industry. Blended gas serves the same applications as traditional natural gas, including heating, power generation, industrial processes and transportation.

Blending's role in decarbonisation

Gas blends offer four key advantages over solely relying on pure hydrogen or biomethane for decarbonising our energy system.

Gas blends maximise the use of existing natural gas networks. This significantly reduces the need for the costly and disruptive replacement infrastructure that would be required for pure hydrogen.

Blending gas allows for a controlled and gradual transition, mitigating the potential safety concerns associated with pure hydrogen. This approach allows safer integration of lower-carbon gases.

Gas blends bridge the gap between current natural gas supply levels and the limited production capacity of the likes of biomethane. This allows for immediate emissions reductions, while renewable gas production scales up in the meantime.

By combining the strengths of different gases, gas blending provides a more robust and reliable energy supply, guaranteeing stability during periods of peak demand while delivering greater energy security too.

The UK’s blending strategy

The UK is pursuing blending as a key part of its energy transition, focusing on both hydrogen and biomethane. By employing a phased approach, the UK aims to gradually decarbonise its gas supply, balancing the use of existing infrastructure with the uptake of clean energy technologies.

Blending is designed to work with existing infrastructure and appliances, though higher concentrations may require performance monitoring. As blending scales up, energy costs may shift to reflect production and integration expenses—making transparency and consumer engagement essential.

For hydrogen, in December 2023 the government committed to supporting blending of up to 20% hydrogen into distribution network. However, safety trials led by the Health and Safety Executive and further research must conclude before the government commit to enabling hydrogen blending.

A decision on transmission blending is also expected soon, as the government considers a ‘minded to’ position to allow blending of up to 2% hydrogen by volume in the transmission network. If supported, it’s anticipated that hydrogen blending at a commercial scale would begin in 2028 at the earliest.

For biomethane, while no formal blending targets exist, its role is growing. NESO’s Future Energy Scenarios report suggests biomethane could supply up to 64 TWh of gas demand by 2050.

NESO has also called for a long-term policy framework to support the biomethane sector beyond the end of the Green Gas Support Scheme in 2028. The framework could also include biomethane targets - similar to those used in countries like France and Denmark - to ensure the market's continued growth and stability.

-

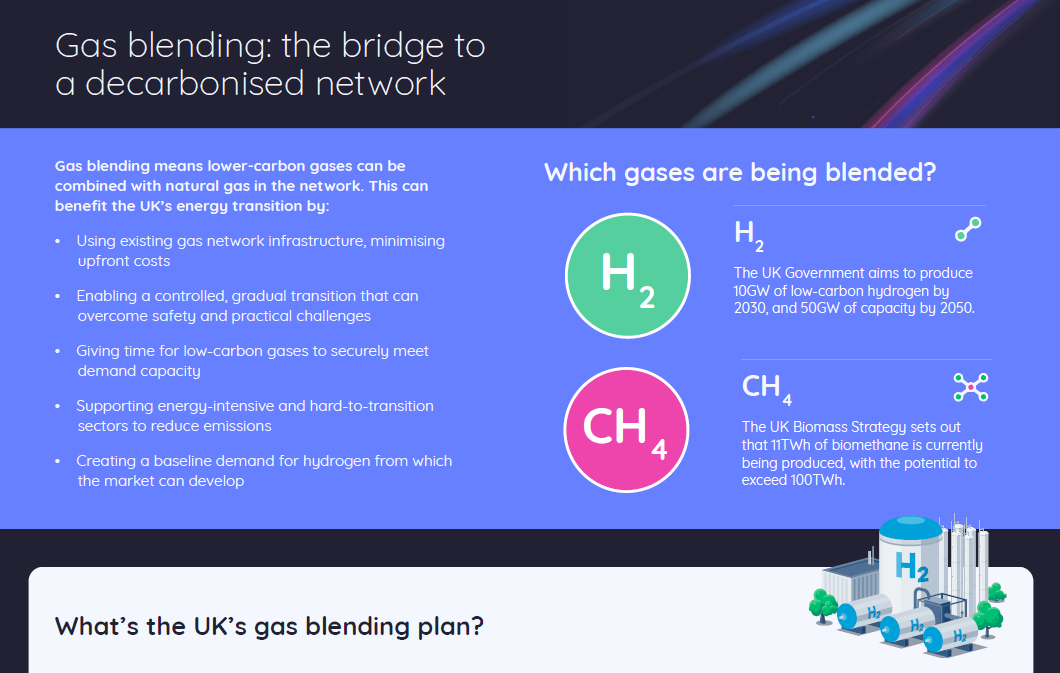

Gas blending: The bridge to a decarbonised network

Gas blending: The bridge to a decarbonised networkOur infographic explaining the gas blending process and the benefits it has in decarbonising our energy system.

PDF, Last Updated 14/10/2025, 514.6 KB

Hydrogen blending

Introducing hydrogen into natural gas pipelines

A hydrogen blend creates a fuel that can be used with existing systems and appliances, a major reason why it's increasingly seen as a pragmatic medium-term tool to decarbonise the gas grid.

It's also particularly useful in helping hydrogen production clusters establish a baseline of demand.

Importantly, blending offers a mechanism to de-risk supply investment, allowing hydrogen to be injected into the system even when dedicated offtake or storage is unavailable. This is especially relevant in resolving the timing mismatch between supply and demand in early-stage hydrogen markets. Blending helps create a functioning market and can serve as a “safety valve” for producers.

The benefits of hydrogen blending

Explore the many benefits of hydrogen blending from reduced emissions to its versatility for a range of applications:

Lower carbon content

When burned, hydrogen produces only water vapour, and no carbon dioxide. With zero emissions at the point of use, hydrogen could play a vital role in moving the UK towards a cleaner energy future.

Reduced emissions

Hydrogen and natural gas blending means the overall carbon content of the fuel is reduced. As a result, for every unit of energy produced, the blended fuel releases fewer greenhouse gas emissions than when compared with pure natural gas.

Easing the energy transition

Hydrogen blending could act as an important bridge towards a fully decarbonised energy system. It’s one potential option on the road to moving away from fossil fuels, which can use existing infrastructure and minimise disruption.

Wide range of sources

Hydrogen can be produced from various sources. These range from steam methane reforming, which is reasonably inexpensive but generates high carbon emissions, to electrolysis, which can have no associated carbon emissions if the electricity is sourced from renewable technologies like solar and wind power, but poses challenges around cost and scalability.

Greater energy independence

The decision to produce more hydrogen domestically means countries like the UK can reduce their reliance on imported fossil fuels, enhancing energy security in the process.

Potential for hydrogen economy

The emerging hydrogen economy has the chance to boost economic growth, while creating new job opportunities in research, manufacturing and development.

Suitable for multiple sectors

From domestic heating and industrial heat, to power generation and transportation, hydrogen blending has the potential to decarbonise a range of sectors that are currently reliant on natural gas.

A versatile solution

Because of its high energy density, hydrogen is ideal for applications like long-distance transportation and heavy-duty industrial uses.

Scalable and storable

Hydrogen has great potential for scalability and storage - but it’s worth noting that significant investment and innovation is required to make this a reality.

Uses existing network

Hydrogen can be easily transported through existing natural gas pipelines - albeit with some modifications for blends with higher percentages of hydrogen - minimising the need for costly new infrastructure.

Minimises disruption

If the decision is made to blend relatively low percentages of hydrogen into the natural gas grid, then household appliances or industrial equipment won’t need to be changed or modified, making the transition to a more sustainable energy system more manageable.

Increased capacity

Blending hydrogen can effectively increase the capacity of the existing gas grid to transport energy, to accommodate the growing demands on the grid, while supporting the integration of renewable energy sources.

How much hydrogen can be blended with natural gas?

The amount of hydrogen that can be safely and effectively blended with natural gas depends on a variety of factors, including:

Gas infrastructure - The age, materials and condition of existing pipelines and equipment can influence the maximum allowable hydrogen concentration. For example, older pipelines may be more susceptible to hydrogen embrittlement.

End-use application - With different appliances possessing different tolerance levels for hydrogen, the application in question can influence blend levels. For instance, industrial processes with high-temperature requirements may have different tolerances than domestic heating.

Safety regulations - Safety guidelines and regulations are critical in defining the acceptable limits for hydrogen blending, safeguarding communities and ensuring gas infrastructure continues to operate as expected.

In the UK, the HyDeploy project has successfully demonstrated the safety and feasibility of blending up to 20% hydrogen in a live gas network. The decision to test at this blend percentage was based on a number of reasons:

- Earlier studies indicated that adding a blend of 20% hydrogen to a network was unlikely to present significant changes to any risks already associated with natural gas delivery.

- 20% is the level at which it is expected that gas customers’ supply and usage will not be affected by the change in gas composition.

- Gas appliances manufactured after 1996 have been designed to operate with a hydrogen blend of up to 23%.

Hydrogen blending challenges

While hydrogen blending offers a promising means of decarbonising the gas grid, several barriers hinder its widespread uptake.

As hydrogen can embrittle some pipeline materials, ongoing research and development are needed to ensure compatibility with increased hydrogen concentrations and prevent potential leaks or damage.

Blending hydrogen also alters the burning properties of natural gas. Consumers must feel confident that appliances and industrial processes are safe and efficient.

With hydrogen’s smaller molecular size compared to methane, existing gas infrastructure requires specialised safeguards too. Advanced leak detection and monitoring systems are essential to mitigate the increased risk of leaks, and ensure the safe operation of pipelines and appliances using hydrogen blends at all times.

Producing low-carbon hydrogen, especially green hydrogen from electrolysis, remains more expensive than natural gas. And while blending of a lower hydrogen percentage can take advantage of existing infrastructure, higher blends will require upgrades and modifications, demanding further investment.

The changes in blend percentages may also impact on billing. At transmission level, there is high pressure and capacity. This drops at the distribution level which can lead to variable blend rates. If these rates hit more than 5%, it can impact the flow weighted average methodology due to the change in calorific value.

There are concerns that this will impact domestic and industrial bills, with infrastructure costs also potentially passed onto consumers.

To accommodate hydrogen blending, existing regulatory standards and codes of practice for natural gas will need to be updated, especially when moving forward with higher hydrogen blends in the future.

To encourage investment in hydrogen blending and accelerate its deployment, supportive policies and incentives will be needed.

While hydrogen blending poses great promise to decarbonise the gas network, greater public awareness about its potential - which addresses safety and reliability concerns - is critical.

Furthermore, a fully considered and robust market for hydrogen will need to be established, and a fully competent and skilled workforce capable of managing hydrogen blended systems will need to be a priority.

Biomethane blending

The benefits biomethane blending

Blending natural gas with biomethane offers many environmental and practical advantages. As a renewable energy source from organic waste, biomethane helps reduce the gas supply’s carbon footprint, supporting decarbonisation goals.

It can also be used within existing infrastructure, making it a cost-effective option. Additionally, it supports local economies, especially in agriculture and waste management.

Find out more on our dedicated biomethane webpage.

How can biomethane blending be made a financially attractive option?

The financial attractiveness of blending natural gas with biomethane comes down to long-term cost benefits, as well as the ability to create strategic revenue streams with the fuel.

First, the long-term cost benefits are considerable. As carbon taxes increase, businesses using biomethane gas blends will enjoy significant cost reductions. Furthermore, domestic biomethane production protects against volatile global fossil fuel prices. When compared with the levels of investment involved for electrification, gas blending that incorporates biomethane is a more cost-effective solution.

Second, businesses can generate new revenue streams. Initiatives like the Green Gas Support Scheme provide direct financial incentives, reducing production costs and creating better margins. The Green Gas Certification Scheme also plays a vital role in creating a valuable trading market for biomethane, through Renewable Gas Guarantees of Origin (RGGOs). These RGGOs can be traded, allowing producers to monetise the renewable nature of their gas. Companies wanting to show they're using renewable gas can buy these RGGOs and then 'retire' them, proving their green credentials.

With growing corporate demand for renewable gas as part of ESG commitments, there looks to be a strong demand for biomethane blends in Great Britain, both now and in the future.

Biomethane blending challenges

Integrating biomethane into existing gas networks presents a set of strategic challenges. Including:

Limited feedstock availability and the current capacity of anaerobic digestion infrastructure impacts the ability to scale biomethane production.

Variations in feedstock and purification processes mean strict control measures are needed. This will ensure consistent biomethane quality and compatibility with existing gas networks.

Connecting distributed biomethane production sites to the gas grid, particularly in rural areas, presents logistical challenges and cost barriers. Ensuring the overall capacity of the distribution network can meet demand is another big challenge.

Building industry and public trust in biomethane requires transparent communication and consistent, data-driven evidence.

.

Managing Different Gases

Xoserve has analysed the impact to CDSP systems of different blending scenarios, including:

- Injection of non-propanated biomethane

- Up to 5% hydrogen blending

- Up to 20% hydrogen blending (with dynamic daily injections)

Read more on our dedicated Managing Different Gases webpage.

More information

If you want to know more about any of the above please email us at decarbonisation@xoserve.com.